The Weiser Wastewater Treatment Facility accelerates nature’s way of cleaning water and is Weiser’s choice to prevent water pollution. It is literally a controlled ecological system using both micro and macro-organisms.

It all starts at our homes and businesses:

Most of us don’t think much about what happens to our water after we brush our teeth, take a shower, or flush the toilet. From homes and businesses wastewater is transported through a network of underground pipes and mechanical lift-stations to the Wastewater Treatment Facility for treatment by multiple processes, removing pollutants before being discharged into receiving waters. (The Snake River)

The City of Weiser owns, operates and maintains more than 20 miles of sanitary sewer lines, three pumping (lift) stations, and one secondary Wastewater Treatment Plant.

Step-1 Step Screen/Headworks

Wastewater entering the Treatment Plant passes through an automated Step Screen and waste-compaction system which removes debris larger than 1/2 inch from the wastewater stream.

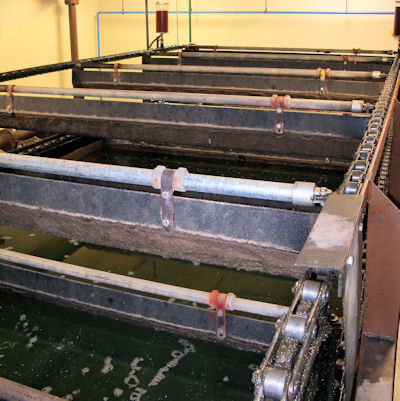

Step-2 Aeration Basins

Four rectangular tanks, each with a capacity of 225,000 gallons and equipped with fine air diffusers, provide an oxygen-rich mixing enviroment for billions of microscopic organisms which use the pollutants in the wastewater for food and also convert ammonia to nitrates, a prime component of fertilizer.

Step-3 Secondary Clarifiers

Our clarifiers are two large circular basins holding 345,000 gallons each. Clarifiers separate organisms and solids from the water for a return trip back to the aeration basins in the form of “Return Activated Sludge” (RAS). Solids settle to the bottom of each clarifier tank and are pumped to “Sludge Digester” tanks for further treatment. (See”Bio-solids Treatment Process” below)

At this stage, over 95% of the pollutants have been removed.

Step-4 Disinfection Contact Chambers

Two concrete tubes that are 6 feet in diameter and 300 feet long each hold 77,000 gallons of water. As water enters the Contact Chambers Chlorine Gas is added to destroy bacteria that survived the previous steps of the treatment process. Additional small particles settle out during this process, further cleaning the water.

Step-5 River Discharge

After treatment and disinfection processes have all been completed, the clean water is released into the receiving waters of the Snake River (NPDES Permit, Outfall 001) which flows into the Columbia River and finally into the Pacific Ocean.

Bio-Solids Treatment Process

Step-1 D.A.F.T.

Solids which have settled to the bottom of the Clarifiers are pumped to the Dissolved Air Flotation Thickener (D.A.F.T.) tank where specially formulated polymers are added to to the mixture to separate floatable solids from the water. The water is returned back to the aeration basins for reprocessing and the solids are pumped to the aerobic digesters.

Aerobic Digesters

The wet solids (sludge) are pumped into Aerobic Digester #1 and mixed with air provided by fine air diffusers. Digester #1 has a capacity of 136,666 gallons. The organic components in the sludge continue to be digested by micro and macro organisms and as digestion continues the mixture is thickened. This process continues until digester #1 reaches capacity, about 42 days.

The contents of Digester #1 is then pumped into Digester #2 which has a capacity of 257,044 gallons. The aeration process continues, further thickening the sludge. After Digester #2 reaches capacity the sludge is pumped to our “Belt Press” process.

Roediger Belt Press

Thickened, digested sludge (wet solids) is pumped from our digesters to a Roediger Belt Press system. Specially formulated Polymers are added to the mixture to aid separation of water from the solids. This mixture is run over a series of rollers between two porous belts which squeezes over 85% of the water out of the solids and loaded into a dump truck using a conveyor belt. The sludge is hauled to the City’s “Drying Beds”.

Drying Beds

The Drying Beds are composed of an asphalt surface with a concrete trench down the middle, a drain pipe and a holding pond for the liquid. The sludge is dumped in rows, turned with a plow blade on a tractor, and rotovated on a regular basis until it is completely dry. After the Bio-Solids dry, a series of tests are performed to assure that all pollutants have been removed and that the bio-solids are beneficial for land application. They are then applied as organic fertilizer to farmer’s fields.